Best HVAC CAD Drafting Services for Ceramic Factory Projects

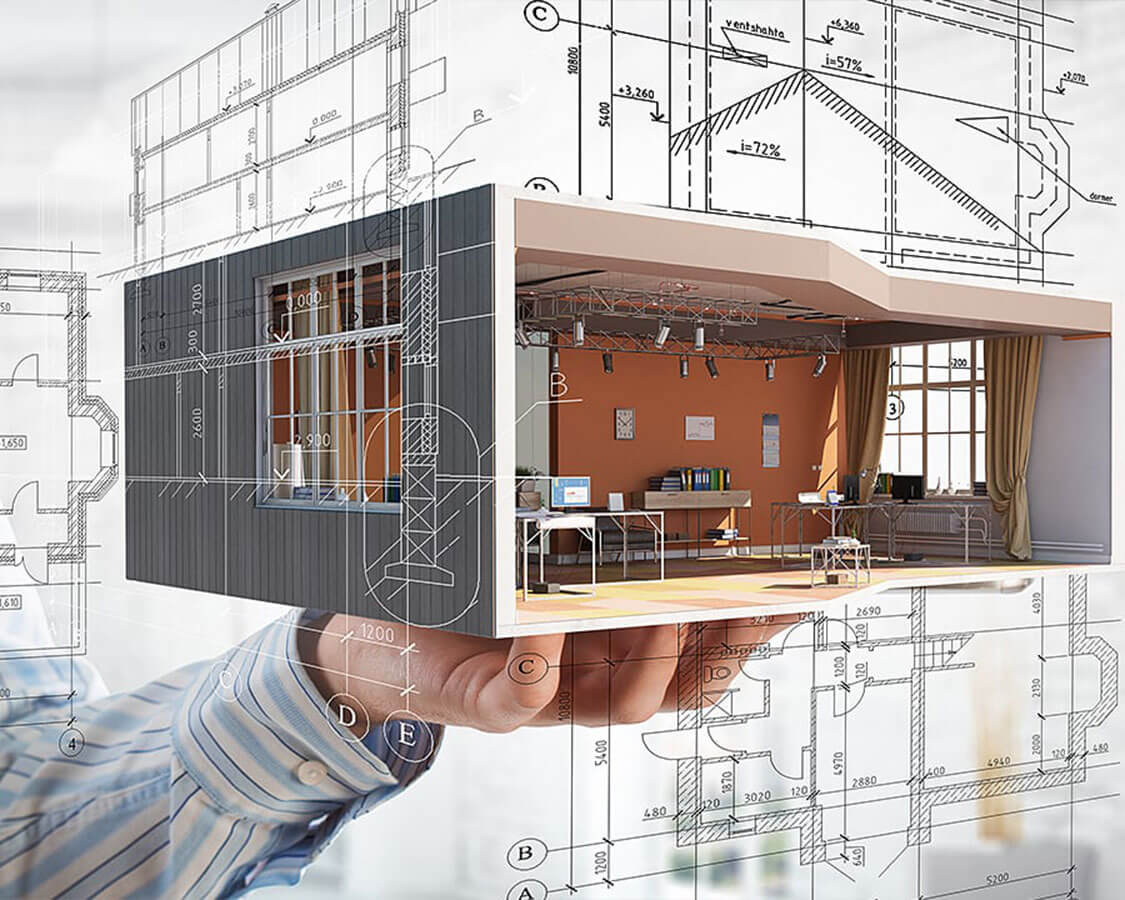

Silicon Valley years of professional MEP and HVAC drafting expertise for your ceramic factory projects. Our drawing professionals understand the airflow and temperature requirements of the raw material storage area, mixing and grinding section, forming and shaping area, drying section, kiln or firing area, administrative and staff areas, and various utility spaces to plan and model customized HVAC CAD and BIM plans. Our staff members are proficient and certified in AutoCAD and Autodesk Revit software, ensuring your 2D and 3D HVAC drawings for ceramic factories are accurate and well-organized.

During ceramic factory planning and development, we communicate in a straightforward manner and ensure that each design iteration is done exactly based on the suggestions our clients give us. Our BIM professionals provide accurate quotes based on the scope of Ceramic factory Development, Planning and Design HVAC, ensuring a balanced approach between performance and expenditure. During HVAC Ceramic factory Planning Management Services, we respond quickly to your feedback and queries and validate that all design decisions align with your operational needs.

Important Drafting and Design Strategies for HVAC Ceramic Factory Projects

Successful HVAC designs in ceramics factories require understanding the intricacies of each stage of the production process. Ceramic factory Development, Planning and Design HVAC Plans primarily concentrate on precise zoning of the heat-intensive zones, implementation of moisture control systems, and utilizing efficient ventilation for kilns and drying units. Besides that, well-planned ducts prevent dust from settling, and energy-saving designs make sure that the airflow remains stable in storage and shaping areas.

Our HVAC Ceramic factory Planning Development, and design documentation reflect a close collaboration between equipment loads, air distribution plans, and temperature zoning maps, which makes it easy for the other MEP systems to coordinate. Each drawing undergoes an examination through the client’s opinion and local authorities’ standards; hence, the environment is not only safe, eco-friendly, and adequately ventilated but also customized to the ceramic industry’s working conditions.

Why Investing in Our CAD Drafting Services Pays Off for Your HVAC Ceramic Factory Projects?

- Specialization in CAD drafting for over 22 years

- Your ongoing input guides every design adjustment

- Our Ceramic factory Planning and Design Services for HVAC meet all required compliance and building guidelines

- Budget-sensitive offering

- Proactive coordination among your project personnel

- Prompt replies and immediate assistance

- Time-conscious CAD design and drafting workflows

Book a consultation today for your HVAC Ceramic Factory projects. We provide accurate CAD and BIM documentation tailored to your specific requirements.