Expanding Possibilities with a Full Range of Sheet Metal Design Services offered by Silicon Valley

Silicon Valley proactively provides Sheet Metal Design Services, which include detailed plans and instructions for accurately shaping and designing the metal sheet to fit the structure perfectly. As a reputed Sheet Metal Design Company, we create highly customized sheet metal solutions that help save production costs, shorten product timelines, reduce wastage, and meet quality and safety standards. Our rich Sheet Metal Design Shop Drawings Services portfolio includes projects in automotive infrastructure, aerospace facilities, metros, skyscrapers, complexes, manufacturing plants, and other sectors.

We create highly descriptive Sheet Metal Design Drawings that include specifications on crucial material factors like strength, weight, corrosion resistance, and others to meet the necessary performance criteria of the structure. Design Service For Sheet Metal by Silicon Valley involves rigorous testing and refining so that the designs meet architects' demands and expectations. We create quality-driven scalable designs that allow for the effortless mass production of metal sheets.

Versatile Sheet Metal Design Services to meet clients' varied expectations and requirements:

Sheet Metal Drafting Services

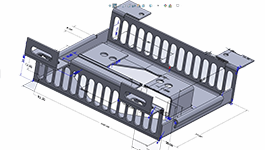

Our Sheet Metal Drafting Services include 2D drawings of sheet metal parts with accurate specifications on dimensions, material type, tolerance, and others. We create a schematic draft for the production and manufacturing process.Sheet Metal Modelling Services

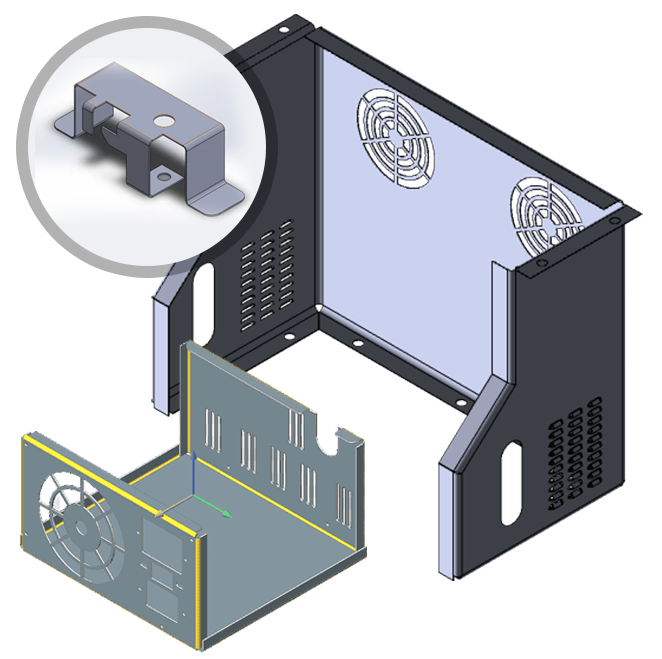

We offer Sheet Metal Modelling Services to AEC professionals and develop 3D BIM Models of sheet metal that help project owners visualize the implementation of sheet metal on buildings accurately and address associated risks.Sheet Metal Shop Drawings Services

Silicon Valley delivers Sheet Metal Shop Drawing Services that comprise a step-by-step guide for effortless fabrication and assembly of sheet metal components in a workshop. We include critical particulars like cutting lists and sustainable material choices.Sheet Metal Detailing Services

Our Sheet Metal Detailing Services focus on the fine details of sheet metal draftings, validating that every component aspect is clearly defined. We specify fasteners, welds, and other elements crucial for the sheet part’s assembly and function.

Sheet Metal Engineering Drawing Services

With Sheet Metal Engineering Drawing Services, we create technical drawings for complex projects and include crucial factors such as strength capacity, bending nature, corrosion properties, and others to make on-site development safer and more productive.

Sheet Metal Part Conversion Services

Sheet Metal Part Conversion Services involve converting existing designs or CAD models into sheet metal-compatible formats. We validate that the new sheet metal parts retain the original design's functionality while gaining strength and durability.

Get Access to Silicon Valley’s Sheet Metal Fabrication Design Services

Sheet Metal Fabrication Design Services is crucial for manufacturing and fabricating accurate sheet metal components. Silicon Valley plans, researches, and executes initial drawings that guide fabricators in producing and manufacturing metal sheets with high sharpness and refinement that help engineers and retailers estimate project costs and timelines.

We provide Sheet Metal Fabrication Drawing Services, including detail-oriented drawings for fabrication and manufacturing processes. Utilizing advanced software, our expert team optimizes drawings for material usage, structural integrity, and ease of production. We thoroughly detail every aspect of the finished metal sheets, from material selection to welding and finishing techniques.

Silicon Valley meets clients' expectations and regulatory requirements with custom Sheet Metal Fabrication Drafting Services. Our highly personalized drafts outline the complete fabrication, including core aspects like stress tolerance, material selection like aluminum, steel, alloy, and others, durability, and several critical parameters to optimize the production process and reduce errors.

Speed Up your Project with Solidworks Sheet Metal Drawing Services provided by Silicon Valley

Silicon Valley holds deep expertise in CAD software, specifically Solidworks, to provide our clients with highly personalized and strategic Solidworks Sheet Metal Drawing Services. With Solidworks, our team automatically generates flat patterns from 3D models, showing how the part will unfold, which helps visualize and manufacture the sheet metal component easily. When we make any changes to the 3D model, SolidWorks automatically updates the associated 2D drawings, validating consistency and reducing the risk of errors.

Look at some critical Solidworks Sheet Metal Drawing Services :

SolidWorks Sheet Metal Design Services

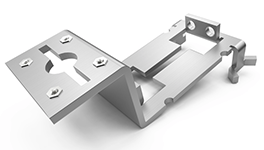

With Solidworks Sheet Metal Designing Services, we utilize advanced features of Solidworks and perform bend & form analysis, flat pattern generation, material, and thickness specification to fasten the production and on-site project work with high quality-control measures.

Solidworks Sheet Metal 3D Modeling Services

Our Solidworks Sheet Metal Modeling Services include creating 3D BIM Models of sheet metal parts, specifying thickness, load concentrations, bends, and other important features. We run simulations within SolidWorks to highlight and eradicate future errors and complications.

We provide Solidworks Sheet Metal Drawing Services for various structural components such as doors, windows, frames, sash, moldings, trims, girls, louvers, shelter structures, awnings, balconies, signage , balustrades, walkways, ramps, stairs, railings, and several others.

A Brief Guide to Sheet Metal Drawing Standards

Sheet Metal Drawing Standards are a crucial parameter for Silicon Valley to consider when creating accurate and consistent drawings for sheet metal components. Standard guidelines validate that the drawings are easy to understand, reduce errors, and improve communication between designers, manufacturers, and quality control inspectors. There are several Sheet Metal Design Standards that elevate safety and performance:

- ISO Standards are international guidelines set by the International Organization for Standardization, which we follow to maintain uniformity, accuracy, and alignment in Sheet Metal Design Drawings to make production and on-site integration easier.

- ANSI Standards are the guidelines set by the American National Standards Institute that clearly define how to illustrate dimensions, materials, and assembly instructions. We obey ANSI guidelines to meet our Sheet Metal Drawings with the US development standards.

- Our detailed drawings adhere to DFM (Design for Manufacturing) Guidelines that improve the manufacturability of sheet metal parts. Sheet Metal Design Drawings include DFM guidelines for part geometry and layout, material selection and processing, tolerancing, surface finish, and fastening and joining methods.

- Some of the Sheet Metal Drawing Standards are ASME Y14.5 for dimensioning and tolerancing, ISO 2768 for general tolerances, DIN 6930 for technical drawings for sheet metal work, AWS D1.3/D1.3M for structural welding code for sheet steel, and ANSI B4.1 for preferred limits and fits.

Partner with Silicon Valley for Sheet Metal Design Outsourcing Services

Global building developers Outsource Sheet Metal Design Services to Silicon Valley to receive innovative and personalized sheet metal drawing solutions. We strategize our Sheet Metal Fabrication Outsourcing Services that meet client's expectations for sheet metal fabrication. We incorporate engineers into our Sheet Metal Drawings Outsourcing Services to get feedback to refine and perfect the design.

Below reasons make AEC professional Outsource Sheet Metal Shop Drawings Services to Silicon Valley :

- Frugal Pricing and Time-Bound Services : We offer competitive pricing Sheet Metal Design Detailing Services without compromising quality. Our team works productively to deliver designs within tight deadlines to avoid project delays and reduce overhead costs.

- Domain Mastery : Our highly experienced team specializes in creating sheet metal drawings with deep knowledge of Steel Detailing Services and software such as Solidworks, Autodesk Inventor, 3DS max, and various others.

- Advanced System and Infrastructure : We utilize advanced design software, hardware, and infrastructure to work on complex Sheet Metal Design CAD Draftings quickly and accurately. Our designs are always up-to-date and boost collaboration and communication among project professionals.

- 99% CAD Drawing Accuracy : We create CAD drawings with Sheet Metal CAD Design Services with a 99% accuracy rate. Our faultless drawings validate that all design details are correct and reduce the risk of errors during manufacturing, leading to reliable and consistent results.

- Secure Digital Environment : We take data security seriously when providing Sheet Metal Design and Modeling Services. Our digital environment is protected by encryption and secure access controls, validating that clients' designs and data are safe from unauthorized access or breaches.

Email us or book a preliminary consultation call with our team regarding your Sheet Metal Modelling Services expectations and requirements. As a trusted Sheet Metal Design Service Provider for over 15+ years, we hold valuable experience in delivering custom Sheet Metal Design and Development Services to resolve major to minor complications and ease fabrication and on-site development.

Frequently Asked Questions

-

What are Sheet Metal Design Services?

Sheet metal design services involve creating detailed designs and drawings for fabricating sheet metal products, such as sheets, plates, and structures from flat sheets. Sheet designs include plans and manuals for on-site assembly to reduce errors and validate safety.

-

What are the key steps in the Sheet Metal Drafting process?

Firstly, experienced designers and drawing professionals create concept designs to outline the project. Then, designs are further detailed to improve accuracy and layout. It is tested to address and resolve issues, and then, after feedback and approval, drawings are finalized and delivered.

-

What is the role of prototyping in sheet metal design?

Prototyping allows designers to create a sample of the sheet metal part before production. Drawing professionals test the design, identify any issues, and make necessary adjustments, validating that the final product is functional and well-designed.

-

What are some major advantages of using CAD software for sheet metal design?

CAD software helps create designs and drawings with high accuracy and helps automate many tasks, resulting in saved time. CAD software helps establish collaboration between project stakeholders and validates consistent data sharing.

-

How do Sheet Metal Drawing Services benefit a structural project?

Sheet metal Drawing Services benefit a structural project with high-accuracy drawings, optimize material usage, and remove wastage. Clear plans help ensure a safer on-site assembly process, budget management, and the project timeline.

-

Which industries benefit from Sheet Metal Design Services?

Sheet Metal Design Services benefits sectors such as aerospace facilities, hospitality infrastructure, penthouses, residential buildings, commercial complexes, metro facilities, industrial plants, educational institutions, etc.

Shop Drawing Services In America Region

-

Antigua and Barbuda

Argentina

Bahia Blanca

Bariloche

Buenos Aires

Comodoro Rivadavia

Cordoba

Corrientes

Formosa

La Plata

La Rioja

Mar Del Plata

Mendoza

Neuquen

Posadas

Puerto Madryn

Quilmes

Resistencia

Rio Cuarto

Rio Gallegos

Rosario

Salta

San Miguel De Tucuman

San Salvador De Jujuy

Santiago Del Estero

Tandil

Trelew

Tucuman

Bahamas

Barbados

Belize

Bermuda

Hamilton

Bolivia

Bots

El Alto

La Paz

Oruro

Potosi

Santa Cruz De La Sierra

Sucre

Tarija

Brazil

Belem

Belo Horizonte

Brasilia

Campinas

Curitiba

Duque De Caxias

Fortaleza

Goiania

Guarulhos

Maceio

Manaus

Natal

Nova Iguacu

Porto Alegre

Recife

Rio De Janeiro

Salvador

Sao Goncalo

Sao Luis

Sao Paulo

Canada

Abbotsford

Alberta

Barrie

Brampton

Calgary

Edmonton

Gatineau

Greater Sudbury

Guelph

Halifax

Hamilton CA

Kelowna

Kingston CA

Kitchener

London CA

Markham

Mississauga

Moncton

Montreal

Ontario

Oshawa

Ottawa

Quebec City

Regina

Saguenay

Saskatoon

Sherbrooke

St Johns

Surrey

Thunder Bay

Toronto

Trois Rivieres

Vancouver

Victoria

Winnipeg

Yellowknife

Caribbean

Chile

Antofagasta

Arica Chile

Chillan

Concepcion

Copiapo

Iquique

La Serena Chile

Puente Alto

Puerto Montt

Quilpue

Rancagua

Santiago

Talca

Temuco

Valparaiso

Vina Del Mar

Colombia

Barranquilla

Bogota

Cali

Cartagena

Cucuta

Medellin

Costa Rica

Cuba

Dominica

Dominican Republic

Ecuador

Guayaquil

Quito

El Salvador

Grenada

Guatemala

Guatemala City

Guyana

Haiti

Honduras

Jamaica

Clarendon Parish

Kingston

Montego Bay

Portmore

Spanish Town

Mexico

Chihuahua

Ciudad Juarez

Ecatepec

Guadalupe

Guadalajara

Hermosillo

Leon

Merida

Mexico City

Monterrey

Puebla

Tijuana

Zapopan

New Mexico

Santa Fe

Nicaragua

Panama

Paraguay

Asuncion

Peru

Lima

Saint Kitts and Nevis

Saint Lucia

Saint Vincent and the Grenadines

Suriname

Trinidad and Tobago

Trinidad

Uruguay

Montevideo

USA

US Virgin Islands

Northern Mariana Islands

Puerto Rico

San Juan

Venezuela

Barquisimeto

Caracas

Ciudad Guayana

Maracaibo