End-to-End Structural Spinning And Weaving Plant Design Services

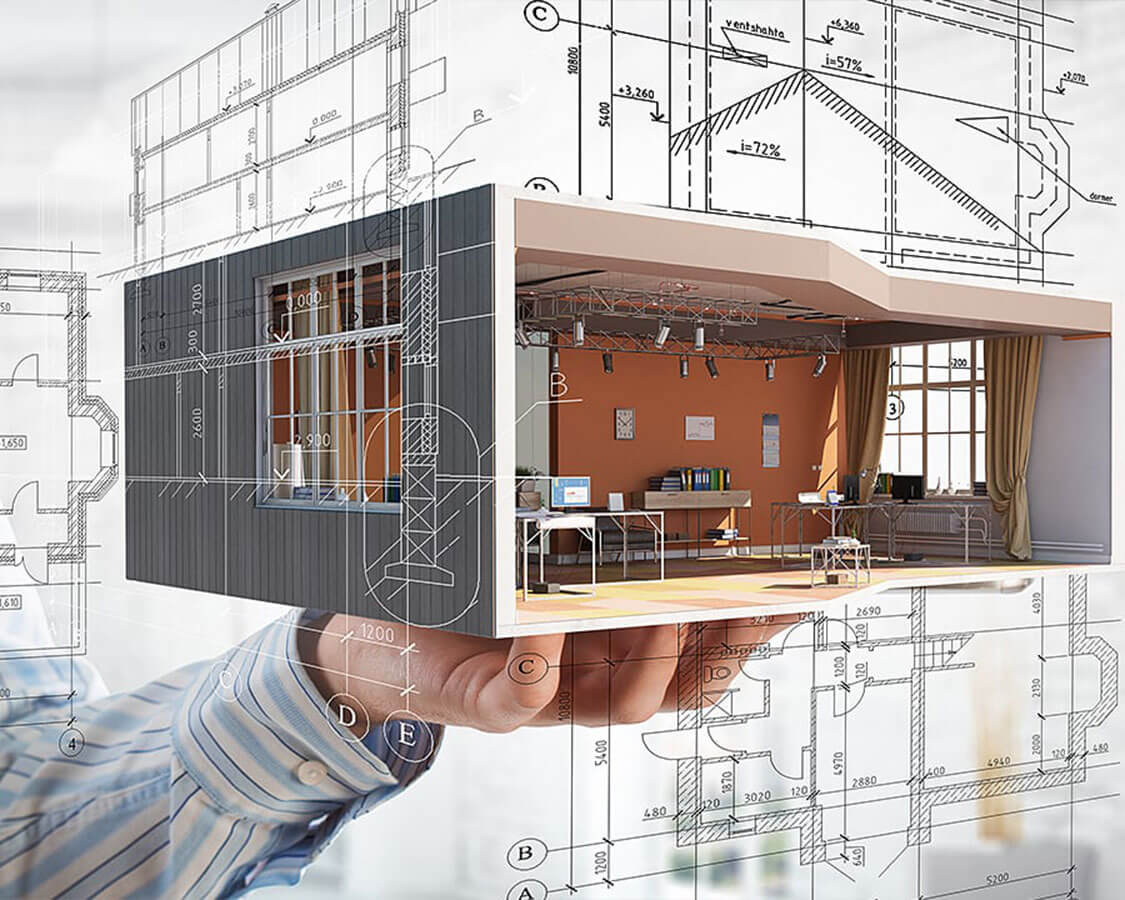

For over 20 years, Silicon Valley has delivered numerous structural engineering projects that fully met local building codes, global best practices, and client specifications, all while being led by our team. The thought behind ideating the Spinning and Weaving Plant Project and executing it in reality are the two ends of a spectrum that need to be connected. The design is that bridge. Our objective with Structural Spinning and Weaving Plant Design Services is to deliver high-grade BIM models, CAD drawings, and erection manuals at an affordable rate that aligns seamlessly with the client’s budget strategy. Working to building codes and standards is a significant priority in our Spinning and Weaving Plant and Design Services offering. This enables our client to achieve structural compliance from the outset, allowing them to focus their resources on production goals.

In addition, our Spinning and Weaving Plant Management Services utilize BIM to help AEC professionals systematically manage projects. In conjunction with that, we provide clarity in project sequencing, real-time cost optimization, and lifecycle management through our Structural and Spinning and Weaving Plant Drawing Services. Our global resonance with AEC professionals stems from our commitment to maintaining transparency, accuracy, and adaptability throughout all phases of Spinning and Weaving Plant Development Services. We offer clarity at every design milestone, empowering clients to make informed decisions while we refine structural intent with engineering accuracy.

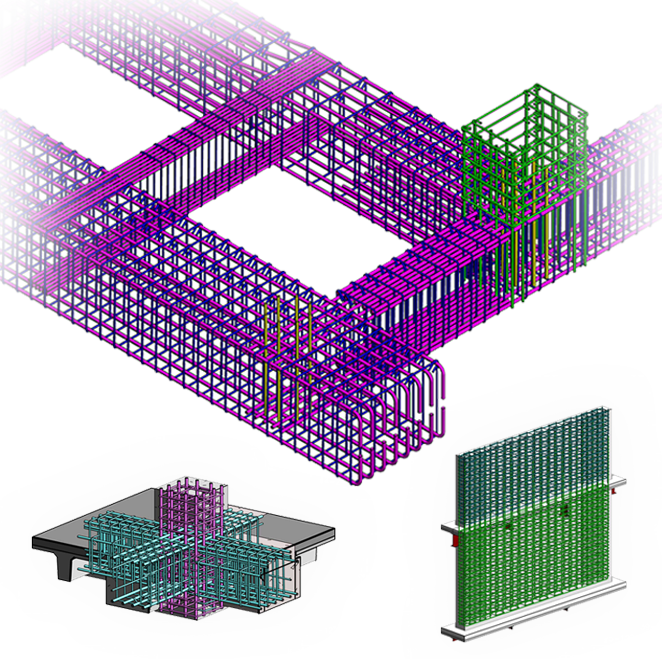

Comprehensive View of Our Spinning and Weaving Plant Modeling Services

To begin our modeling process, we collect client input, process flow diagrams, equipment locations, and layouts. We convert the information to a fully developed structural model that includes all columns, beams, slabs, machine foundations, mezzanine floors, roof systems, and all other load-bearing elements. Our model is more than just visualization; it can also help detect conflicts at an earlier stage in a project and facilitate more efficient coordination with other disciplines, such as MEP and architectural design. A model serves as an asset for each project member to review and approve the design with greater clarity and confidence.

How Spinning and Weaving Plant Modeling Services Benefit our Clients?

- Project budget planning and prediction

- Accurate machine foundation planning

- Construction scheduling and event planning

- Managing space better and optimized

- As-built record for lifecycle support

- Easily adjustable structural models

Compelling Reasons to Outsource Structural Spinning And Weaving Plant Design Services to Us

- Delivery-oriented project plan

- Budget-conscious service offerings

- High-grade quality through high-end software

- Compliant with regional structural standards

- Client-centric approval process

- Fast-response assistance

Begin your textile manufacturing project with a solid structural foundation. Our experience in creating spinning and weaving plants enables us to deliver customizable, reliable layouts, material optimizations, and infrastructure that will remain relevant for years to come. Contact us today to discuss Structural Spinning and Weaving Plant Services and schedule an appointment with our engineering specialists.

Structural Services In Leading Cities Of The United States

United States Of America

North East Region

-

Connecticut

Bridgeport

Stamford

New Haven

Hartford

Waterbury

Maine

Lewiston

Bangor

South Portland

Auburn

Biddeford

Massachusetts

Boston

Worcester

Springfield

Cambridge

Lowell

New Hampshire

Manchester

Nashua

Concord

Derry

Londonderry

New Jersey

Newark

Jersey City

Paterson

Elizabeth

Trenton

New York

New York City

Buffalo

Rochester

Yonkers

Syracuse

Albany

Long Island

Niagara

Pennsylvania

Philadelphia

Pittsburgh

Allentown

Reading

Erie

Rhode Island

Providence

Warwick

Cranston

Pawtucket

East Providence

Vermont

Burlington

South Burlington

Rutland

Essex Junction

Barre

Midwest Region

-

Illinois

Chicago

Aurora

Joliet

Naperville

Rockford

Indiana

Indianapolis

Fort Wayne

Evansville

South Bend

Fishers

Iowa

Des Moines

Cedar Rapids

Davenport

Sioux City

Iowa City

Kansas

Wichita

Overland Park

Olathe

Topeka

Lawrence

Michigan

Detroit

Grand Rapids

Warren

Sterling Heights

Ann Arbor

Minnesota

Minneapolis

Saint Paul

Bloomington

Duluth

Brooklyn Park

Missouri

Kansas City

Saint Louis

Columbia

Independence

Lees Summit

Nebraska

Omaha

Lincoln

Grand Island

Kearney

Fremont

Nelson

North Dakota

Fargo

Bismarck

Grand Forks

Minot

West Fargo

Ohio

Columbus

Cleveland

Cincinnati

Toledo

Akron

South Dakota

Sioux Falls

Rapid City

Aberdeen

Brookings

Watertown

Wisconsin

Milwaukee

Madison

Green Bay

Kenosha

Racine

South Region

-

Alabama

Huntsville

Montgomery

Birmingham

Mobile

Tuscaloosa

Arkansas

Little Rock

Fayetteville

Fort Smith

Springdale

Jonesboro

Delaware

Wilmington

Dover

Middletown

Smyrna

Brookside

Florida

Jacksonville

Miami

Tampa

Orlando

St. Petersburg

Hialeah

Maitland

Georgia

Atlanta

Sandy Springs

Augusta

Macon

Savannah

Kentucky

Louisville

Lexington

Bowling Green

Owensboro

Covington

Louisiana

New Orleans

Baton Rouge

Shreveport

Lafayette

Lake Charles

Maryland

Baltimore

Frederick

Gaithersburg

Rockville

Bowie

Mississippi

Jackson

Gulfport

Southaven

Biloxi

Hattiesburg

North Carolina

Charlotte

Raleigh

Greensboro

Durham

Winston-Salem

Oklahoma

Oklahoma City

Tulsa

Norman

Broken Arrow

Edmond

South Carolina

Charleston

North Charleston

Mount Pleasant

Rock Hill

Greenville

Tennessee

Nashville

Memphis

Knoxville

Chattanooga

Clarksville

Texas

Houston

San Antonio

Dallas

Austin

Fort Worth

Corpus Christi

El Paso

Garland

Laredo

Lubbock

Plano

Virginia

Virginia Beach

Chesapeake

Norfolk

Richmond

Newport News

Alexandria

Arlington

West Virginia

Huntington

Parkersburg

Morgantown

Wheeling

Weirton

Washington DC

West Region

-

California

Irvine

Los Angeles

San Diego

San Jose

San Francisco

Fresno

Anaheim

Bakersfield

Chula Vista

Long Beach

Modesto

Monrovia

Oakland

Riverside

Sacramento

San Bernardino

San Lorenzo

Santa Ana

Santa Cruz

Santa Rosa

Stockton

Washington

Seattle

Spokane

Tacoma

Vancouver

Bellevue

Oakville

Arizona

Phoenix

Scottsdale

Tucson

Mesa

Chandler

Gilbert

Glendale

Colorado

Denver

Colorado Springs

Fort Collins

Lakewood

Thornton

San Luis

Windsor

Oregon

Portland

Salem

Eugene

Gresham

Hillsboro

Utah

Salt Lake City

West Valley City

West Jordan

Provo

Saint George

Nevada

Las Vegas

Henderson

North Las Vegas

Reno

Sparks

New Mexico

Albuquerque

Las Cruces

Rio Rancho

Santa Fe

Roswell

Idaho

Boise

Meridian

Nampa

Idaho Falls

Caldwell

Mackay

New Plymouth

Hawaii

Honolulu

East Honolulu

Pearl City

Hilo

Waipahu

Montana

Billings

Missoula

Great Falls

Bozeman

Butte

Alaska

Anchorage

Fairbanks

Juneau

Wasilla

Sitka

Wyoming

Cheyenne

Casper

Gillette

Laramie

Rock Springs